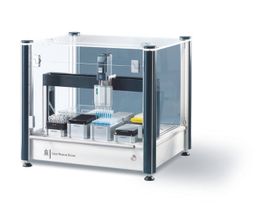

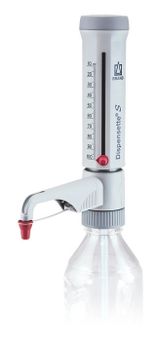

Laboratory Tools for Chemistry and Life Science

Recommended Products

Recommended Products

Welcome to VACUUBRAND

Bitte wählen Sie Ihr Land, damit wir

Ihnen alle bei Ihnen verfügbaren Produkte anzeigen können.

Global

Your country is not included? Visit our

global shop