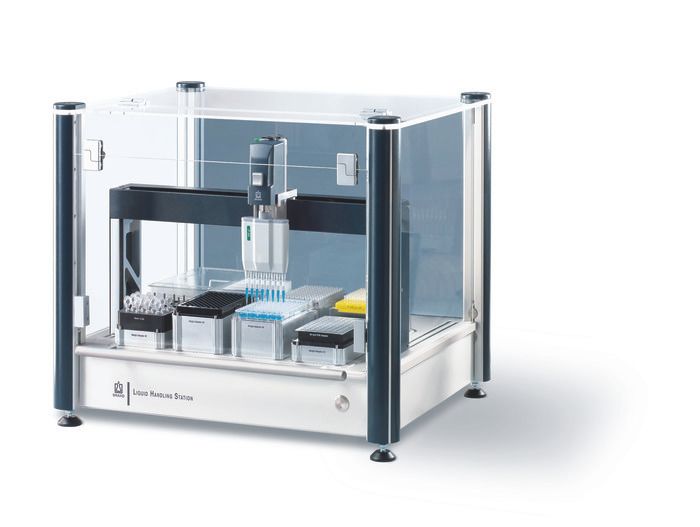

Pipetting robot Liquid Handling Station

Overview

- Extremely versatile, e.g. for PCR, enzyme tests and many other applications.

- Quick and uncomplicated method creation.

- Maximum performance at an attractive price.

| Cat.-No. | Product Description |

|---|---|

| 709400 | Liquid Handling Station Pipetting robot |

| 709402 | Liquid Handling Station flow, Pipetting robot With FlowBox |

| Price per | Price | ||

|---|---|---|---|

Product Detail

The Liquid Handling Station provides maximum flexibility for small and medium sample throughput and varied pipetting tasks. It closes the gap between electronic pipettes and large, expensive equipment.

Seven ANSI / SLAS formatted workplaces can be freely assigned, including PCR tubes and strips, microcentrifuge tubes, reservoirs, and 96- or 384-well plates. Liquid ends are available in single-channel sizes and 8-channel versions for contact-free fluid delivery. The Liquid Handling Station's compact design and space-saving front door make it an ideal fit where benchtop space is limited.

With an excellent price/performance ratio and straightforward operation, the system is economical for low and medium throughput labs. Typical applications include:

PCR and qPCR

ELISA

Enzyme assays

Cherrypicking

Items supplied

Pipetting robot Liquid Handling Station incl. motor control unit, operating software, user manual, power cable, USB cable, documentation, and on-site training. Liquid Handling Station flow additionally with FlowBox filtration unit.

für Zoom klicken

für Zoom klicken

Resources

Videos

Related Products

| Cat.-No. | Product Description |

|---|---|

| 709400 | Liquid Handling Station Pipetting robot |

| 709402 | Liquid Handling Station flow, Pipetting robot With FlowBox |

| Price per | Price | ||

|---|---|---|---|

Product Detail

The Liquid Handling Station provides maximum flexibility for small and medium sample throughput and varied pipetting tasks. It closes the gap between electronic pipettes and large, expensive equipment.

Seven ANSI / SLAS formatted workplaces can be freely assigned, including PCR tubes and strips, microcentrifuge tubes, reservoirs, and 96- or 384-well plates. Liquid ends are available in single-channel sizes and 8-channel versions for contact-free fluid delivery. The Liquid Handling Station's compact design and space-saving front door make it an ideal fit where benchtop space is limited.

With an excellent price/performance ratio and straightforward operation, the system is economical for low and medium throughput labs. Typical applications include:

PCR and qPCR

ELISA

Enzyme assays

Cherrypicking

Items supplied

Pipetting robot Liquid Handling Station incl. motor control unit, operating software, user manual, power cable, USB cable, documentation, and on-site training. Liquid Handling Station flow additionally with FlowBox filtration unit.

für Zoom klicken

für Zoom klicken

Resources

Videos